Creating Energy: How Suncor Energy Collaborates to Innovate

May 29, 2025 | Dawn Zoldi

Suncor Energy’s drone program stands as a model for how legacy energy giants can embrace new technology to drive efficiency, safety and environmental stewardship at scale. Since launching its formal drone operations in 2020, Suncor has completed more than 18,000 missions across Canada and the United States, transforming everything from mine surveys to wildlife protection.

By combining internal expertise with a robust network of 32 external vendors, Suncor has built one of North America’s most advanced hybrid drone programs – one that is not only reshaping industrial inspection and maintenance, but also setting new standards for regulatory compliance and data management. In a recent Dawn of Autonomy podcast, Tedman Jess, Senior Aviation Advisor – RPAS, provided a deep dive into the approach that has helped Suncor turn drones from a niche experiment into a core operational asset.

A Veteran Aviator at the Helm: Tedman Jess

Tedman Jess brings more than two decades of aviation experience to his role as Senior Aviation Advisor – RPAS at Suncor Energy. Raised around helicopters and bush planes thanks to his father’s career as a helicopter pilot, Jess earned his private pilot license after university but soon gravitated toward aviation operations. He built his early career with a Calgary-based charter airline before joining Suncor in 2014 to support its renowned fly-in, fly-out aviation program for oil sands workers, to allow workers to commute to remote sites via plane and get to spend more time with their families.

Jess’ passion for aviation led him to start tinkering with drones on his own. After realizing their operational potential, he convinced Suncor’s leaders to allow him to create Suncor’s drone program. What began as a small test bed, turned into a full-time position for him by 2020.

Under his leadership, Suncor’s drone operations have grown from those initial 250 flights in 2019 to over 5,000 missions annually by 2024. As of today, he and his team have completed nearly 18,000 flights in just five years. In recognition of his impact, Wings Magazine named Jess one of its Top 20 Under 40 in 2022.

Suncor Energy: From Oil Sands Pioneer to Integrated Energy Leader

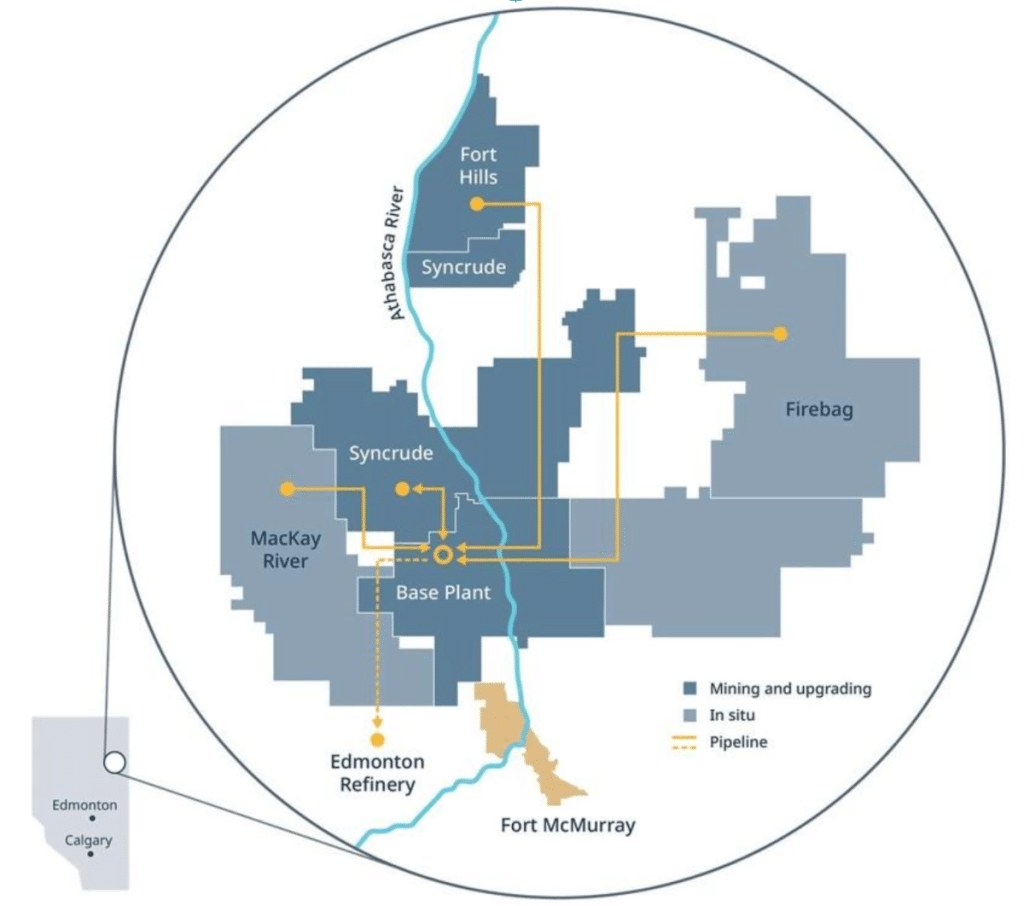

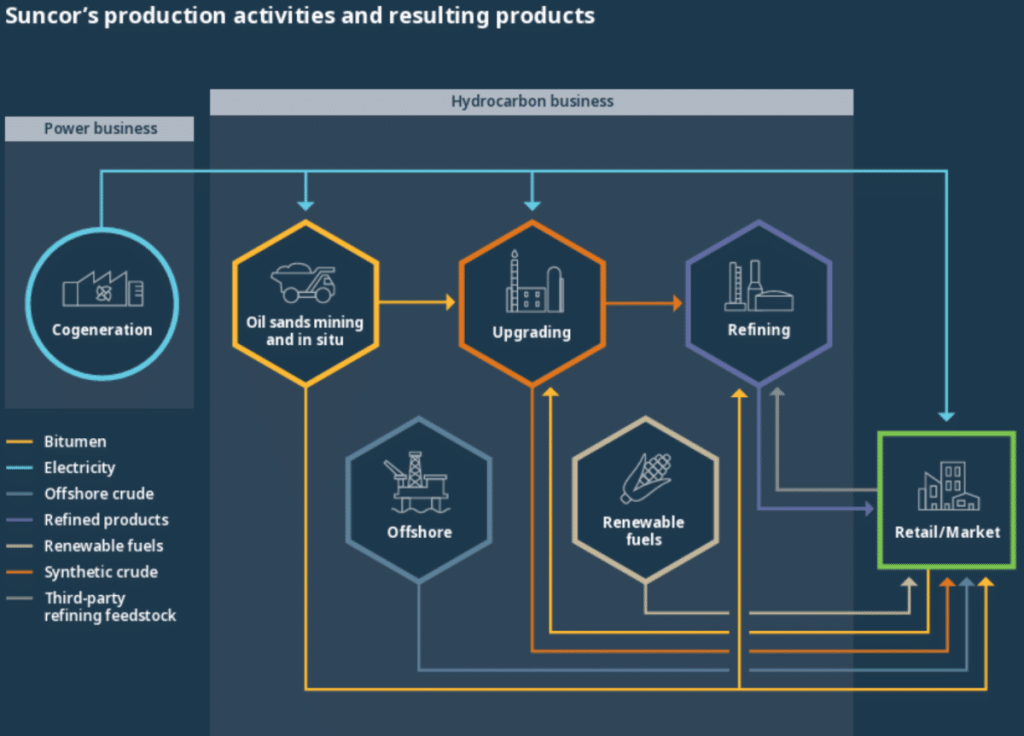

Suncor’s story began in 1967 as a pioneer in the commercial development of Canada’s oil sands. Over the decades, the company has evolved into a fully integrated energy powerhouse. It has operations spanning oil sands mining and in-situ extraction in Alberta, offshore oil production in Newfoundland, refining in Colorado and a coast-to-coast retail network through Petro-Canada. Suncor’s six major sites in northern Alberta alone cover more than 1,800 square kilometers and encompass four open-pit mines and two steam-assisted gravity drainage (SAGD) operations.

Beyond oil and gas, Suncor is Alberta’s third-largest electricity producer. It generates power through cogeneration facilities that feed both its operations and the provincial grid.

Aviation at Suncor: From Crewed Aircraft to Drones

The company’s aviation program is equally vast, as aviation has long been central to Suncor’s operations. Suncor’s aviation ops include everything from helicopters for offshore rigs to aircraft for environmental assessment and pipeline monitoring.

The company’s fly-in, fly-out program, operational since 2008, is so extensive that by passenger volume alone, it would rank as Canada’s fourth-largest airline. According to Jess, the aviation team’s remit is simple: “If it flies, call us.”

As Suncor’s footprint expanded, so did the need for more agile, efficient and safer aerial solutions. Jess explained that the company’s use of drones began as a handful of hobbyist flights and ad hoc vendor requests in 2017.

The introduction of Section 9 of the Canadian Aviation Regulations in 2019 provided the regulatory clarity Suncor needed to formalize and scale drone operations. Jess’s aviation background ensured that Suncor’s drone program would be built on the same rigorous safety and compliance standards as its crewed aviation operations.

How Drones Power Suncor’s Operations

Surveying and Mapping: The Backbone of Drone Operations

The majority of Suncor’s drone missions focus on high-frequency surveying and volumetric mapping of open-pit mines.

“Eighty to ninety percent of our flights are survey missions in our open-pit mine,” Jess explained. He continued, “We are mapping the surface changes and the volumes of material that are moved on a daily basis… By the time we get the data back, if it’s more than two days old, it is now useless. We need valuable, accurate data that we can make decisions on in a timely manner.”

And so now drones fly daily to capture the shifting landscape. They provide centimeter-level accuracy on material movement, mine progression and road conditions. This data has become essential for billing contractors, mine planning and ensuring operational efficiency.

Safety and Cost Savings

Drones have dramatically improved safety by removing personnel from hazardous environments. Instead of survey crews navigating between massive shovels and mine walls or climbing scaffolding for inspections, a single drone pilot can complete the task remotely. This reduces risk and downtime.

“Our exposure footprint is shrinking,” Jess noted. “We’re not sending our crews into dangerous environments like the mining environment. We can actually take survey crews and boots on the ground out of the field and replace them with one drone pilot.”

The result: increased productivity, faster data turnaround and significant cost savings – sometimes in the hundreds of thousands of dollars per inspection.

Expanding Applications: From Bird Hazing to Power Line Inspections

Suncor’s drone program isn’t limited to mining. It uses drones to:

- Chase birds from tailings ponds using radar-triggered flights and bird-shaped drones with predator calls. This protects wildlife and meets environmental compliance.

- Inspect high-voltage transmission lines with multi-sensor payloads. This replaces costly and fuel-intensive helicopter flights.

- Perform offshore ship inspections on the Terra Nova FPSO vessel. This allows for safer and more comprehensive checks without putting workers at risk.

- Road Surveys and AI-Driven Insights with the University of Toronto’s mining school, Suncor also uses drones and machine learning for haul road analysis. By mapping 50 kilometers of mine roads with centimeter accuracy, the company can identify deficiencies and prioritize repairs. The project aims to reduce tire wear on trucks and save millions in maintenance costs.

The Hybrid Model: Internal and Contracted Resources

Suncor’s drone program is built on a hybrid operational model that combines internal pilots and leased drones with a robust network of third-party service providers. This approach maximizes flexibility and ensures access to the latest technology and specialized expertise.

Leasing, Not Buying: Staying Ahead of the Curve

Rather than purchasing drones outright, Suncor leases its fleet. This strategy allows the company to keep pace with rapid technological advancements and ensure that employees always have access to the most capable platforms and sensors without the burden of depreciation or obsolescence.

“By leasing the drones, we can keep up with the technology curve,” Jess said. “We’re trying to get the best platform and the best sensor at the most reasonable cost into the hands of our folks in the field.”

Training and Empowerment

Suncor’s internal drone pilot program began with survey crews, employees with deep site knowledge but little aviation experience. Through a comprehensive six-day training course (three days in the classroom, three days hands-on), employees earn their advanced pilot certificates and become eligible to operate drones for their business units. This empowers long-standing staff to leverage new technology without replacing their roles. It also preserves institutional knowledge while enhancing capabilities.

Jess elaborated, “The people haven’t changed, which is very nice because we’ve had people who have been in our company for 20 years on site.The fact that we’re just able to give them a drone in their hands now to be able to go out and capture the data is huge.”

Strategic Vendor Partnerships: The Osprey Integrity Relationship

For specialized tasks and scalable operations, Suncor relies on trusted partners like Courtland Penk of Osprey Integrity. These vendors bring niche expertise and advanced tools, such as non-destructive testing (NDT) drones, that would be impractical for Suncor to utilize in-house. This collaborative approach ensures that Suncor can tackle both routine and complex challenges efficiently.

Penk provided his perspective on his company’s partnership with Suncor. “We’re using very similar tools, very similar processes, but with a specific subject matter expertise with respect to deficiencies in a fixed plant environment,” he said. “When we come away from the data review, we have essentially a heat map-a treasure map-of spots to go and do some very targeted, very specific follow-up.”

The 3S’s of ROI: Safety, Speed and Savings

According to Jess, the return on investment (ROI) for Suncor’s drone program is clear:

- Safety: Fewer boots on the ground in hazardous areas equates to fewer incidents.

- Drones: Drones have reduced data turnaround times from days to hours.

- Cost Savings: Eliminating the need for scaffolding, cranes or helicopter flights saves hundreds of thousands of dollars per project.

- Operational Efficiency: Near real-time data, mine planning and maintenance decisions improves its accuracy and timeliness.

As one example, Jess noted, “For a flare stack inspection, we’d have to shut down the plant, build scaffolding, put people at height. Now, give us an hour and we can complete that task, saving us hundreds of thousands of dollars.”

What’s Next: Scaling Up with Autonomy and AI

Looking ahead, Suncor seeks to scale its drone operations even further. The company continues to closely watch regulatory changes across North America that will enable routine beyond visual line of sight (BVLOS) flights. It has plans for trials of autonomous docked drone solutions in hopes that fixed drone stations across sites will eventually perform scheduled inspections and data collection without the need for on-site pilots.

“Where I see our program going in the next five years is that we’ll actually phase out pilots in the field and start to deploy them from fixed spots around our sites, capturing the data with a docked solution,” Jess revealed.

Suncor is also investing in data management infrastructure and advanced analytics, including AI-driven triage of drone data to deliver actionable insights faster. The company is also exploring the potential of drone swarms for large-scale operations and solutions for GPS-challenged environments to ensure that its drone program remains at the cutting edge of industrial innovation.

Collaboration as the Catalyst for Innovation

Suncor’s drone program exemplifies the power of collaboration – between experienced aviators like Tedman Jess, skilled employees, innovative vendors and academic partners. By blending internal expertise with external innovation, Suncor has built a flexible, future-proof aviation program that delivers tangible value across its vast energy portfolio. As regulations evolve and technology advances, Suncor appears ready to continue leading the next wave of energy operations in a safer, smarter and more sustainable way than ever before.

- Podcast